mechtechglobal18@gmail.com - GST NO. : 07AWSPR4832K1ZS

- Send Email

| Payment Mode | Online & offline |

| Type | Ultrasonic Inspection And Leak Detection Service |

| Usage | Identifying Hidden Leaks In Compressed Air, Gas, Steam, And Vacuum Systems |

| Capabilities | Compressed Air Leak Detection, Gas Leak Detection |

| Click to view more | |

Service Details

Ultrasonic Inspection & Leak Detection Services

Reliable Detection of Air, Gas, Steam, and Vacuum Leaks Using Advanced Ultrasonic Technology

Reliable Detection of Air, Gas, Steam, and Vacuum Leaks Using Advanced Ultrasonic Technology

At Mech Tech Global, we offer Ultrasonic Inspection and Leak Detection Services designed to identify hidden leaks and inefficiencies in compressed air, gas, steam, and vacuum systems. Using state-of-the-art ultrasonic leak detectors, our expert engineers quickly locate even the smallest leaks — helping industries reduce energy losses, maintenance costs, and unscheduled downtime.

Our inspection process follows international standards and supports predictive maintenance programs, ensuring your facility operates at maximum efficiency and safety.

⚙️ Our Ultrasonic Leak Detection Capabilities

We specialize in:

Compressed Air Leak Detection – Detecting leaks in air pipelines, fittings, hoses, and valves.

Gas Leak Detection – Identifying leaks in nitrogen, oxygen, argon, and other gas systems.

Vacuum Leak Detection – Locating vacuum losses in production or packaging systems.

Steam Trap Inspection – Detecting malfunctioning or failed traps that cause steam loss.

Valve Leak Monitoring – Identifying internal valve leaks or seat damage using ultrasonic signals.

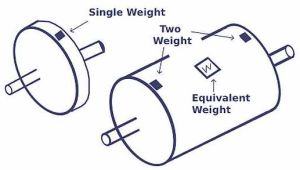

Our technicians use advanced portable ultrasonic detectors such as the EXAIR 9207 Ultrasonic Leak Detector, ensuring fast, precise, and non-intrusive testing.

🧩 Key Benefits

✅ Rapid identification of air, gas, and steam leaks

✅ Reduced energy and operational costs

✅ Improved system efficiency and equipment performance

✅ Enhanced workplace safety and reliability

✅ Non-destructive, real-time testing

✅ Detailed inspection reports for maintenance planning

📋 Our Inspection Process

Initial Assessment: Review system layout and identify potential leak zones.

Ultrasonic Scanning: Use advanced sensors to locate leaks by detecting high-frequency sound waves.

Leak Quantification: Measure leak intensity and estimate energy loss value.

Reporting: Provide a detailed Leak Detection Report with photographic evidence and repair recommendations.

Post-Repair Verification: Confirm successful leak elimination and system performance improvement.

🌍 Industries We Serve

Manufacturing and Process Plants

Food & Beverage Industries

Power Generation & Utilities

Cement and Steel Plants

Automotive and Aerospace Industries

HVAC and Facility Maintenance

🏆 Why Choose Mech Tech Global

Certified engineers trained in ultrasonic technology

Portable instruments for on-site inspections

OEM and ISO-compliant inspection procedures

Proven results in energy savings and system optimization

Integration with condition monitoring programs

📞 Contact Us

Discover how Mech Tech Global can help you save energy and improve reliability through advanced Ultrasonic Leak Detection Services.

🔍 SEO Keywords for Google Optimization

Ultrasonic leak detection services India

Compressed air leak detection Delhi

Steam trap and valve leak inspection

Ultrasonic gas leak testing

Vacuum leak detection experts

Industrial energy loss inspection

Predictive maintenance services India

Leak detection using ultrasonic technology