mechtechglobal18@gmail.com - GST NO. : 07AWSPR4832K1ZS

- Send Email

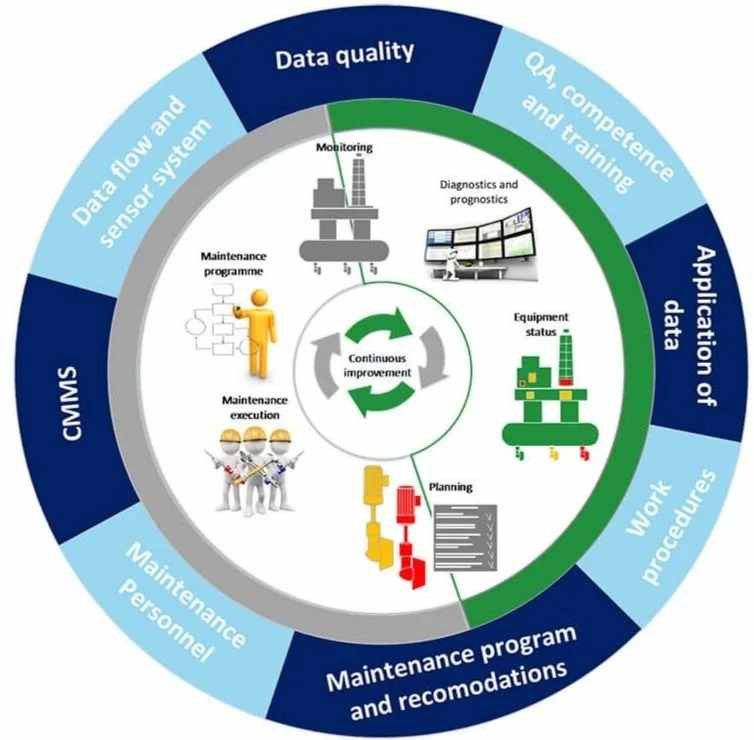

Condition Monitoring Services

Leading Exporters, Wholesaler, Trader, Distributor and Importer of Bearing Condition Monitoring Service, Condition Based Maintenance, Dual Plane Balancing Service, On Site Fan Motor Balancing Service, On Site Vibration Analysis Service, Rotating Machinery Diagnostics Service and Rotor Pump Balancing Service from Delhi.

| Type | Service |

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Usage | Bearing Condition Analysis And Predictive Maintenance |

| Specialty | Vibration Analysis, Ultrasonic Testing, Temperature Monitoring |

| Root Causes Of Failure | Lubrication Issues, Bearing Wear |

| Equipment | Advanced Analyzers (9080, 107VF, Fluke, Etc.) |

Bearing condition analysis and predictive maintenance to prevent unplanned breakdowns

Bearing Condition Analysis and Predictive Maintenance to Prevent Unplanned Breakdowns

At Mech Tech Global, we deliver bearing condition analysis and predictive maintenance services to help industries achieve maximum machinery uptime and reliability. Using advanced vibration analysis, ultrasonic testing, and temperature monitoring, our experts detect early signs of bearing wear, lubrication failure, and mechanical faults — long before they lead to costly breakdowns.

⚙️ Our Expertise

We specialize in assessing and monitoring the health of bearings across various types of rotating equipment, including:

Electric Motors and Generators

Pumps and Fans

Compressors and Blowers

Gearboxes and Turbines

Our bearing condition monitoring programs are designed to identify root causes of failure such as:

Lubrication issues (under/over lubrication)

Bearing wear and pitting

Shaft misalignment

Unbalance and looseness

Structural resonance and fatigue

📈 Benefits of Bearing Condition Analysis

Early fault detection to avoid unplanned shutdowns

Optimized maintenance schedules based on actual equipment health

Reduced downtime and repair costs

Improved equipment performance and reliability

Extended bearing and machine life

🔬 Our Predictive Maintenance Approach

Data Collection: High-accuracy vibration and ultrasonic measurements.

Condition Assessment: FFT spectrum and envelope analysis to detect bearing faults.

Root Cause Diagnosis: Identify source of failure—mechanical, lubrication, or installation-related.

Action Plan: Provide maintenance recommendations and corrective actions.

Periodic Monitoring: Trend analysis to track bearing health over time.

🌟 Why Choose Mech Tech Global

✅ Certified vibration and reliability engineers

✅ Use of advanced analyzers (9080, 107VF, Fluke, etc.)

✅ Comprehensive predictive maintenance solutions

✅ Quick turnaround with detailed diagnostic reports

✅ Trusted by top industrial clients across India

🧾 Industries We Serve

Power Generation & Utilities

Cement, Steel & Mining

Petrochemical & Refinery

Automotive & Process Plants

Paper, Textile & Food Industries

📞 Contact Us

For bearing condition analysis and predictive maintenance services, connect with Mech Tech Global today:

🔍 SEO Keywords for Google Optimization

Bearing condition monitoring services India

Predictive maintenance for rotating machinery

Bearing vibration analysis

Early bearing fault detection

Machinery health monitoring

Condition-based maintenance solutions

Bearing diagnostics and predictive analytics

Industrial maintenance service Delhi NCR

| Type | Condition Based Maintenance |

| Usage | Unplanned Breakdowns Through Bearing Condition Analysis |

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Approach | Data Collection, Condition Assessment, Root Cause Diagnosis |

| Duration | 3 To 4 Days |

Bearing condition analysis and predictive maintenance to prevent unplanned breakdowns

Bearing Condition Analysis and Predictive Maintenance to Prevent Unplanned Breakdowns

At Mech Tech Global, we deliver bearing condition analysis and predictive maintenance services to help industries achieve maximum machinery uptime and reliability. Using advanced vibration analysis, ultrasonic testing, and temperature monitoring, our experts detect early signs of bearing wear, lubrication failure, and mechanical faults — long before they lead to costly breakdowns.

⚙️ Our Expertise

We specialize in assessing and monitoring the health of bearings across various types of rotating equipment, including:

Electric Motors and Generators

Pumps and Fans

Compressors and Blowers

Gearboxes and Turbines

Our bearing condition monitoring programs are designed to identify root causes of failure such as:

Lubrication issues (under/over lubrication)

Bearing wear and pitting

Shaft misalignment

Unbalance and looseness

Structural resonance and fatigue

📈 Benefits of Bearing Condition Analysis

Early fault detection to avoid unplanned shutdowns

Optimized maintenance schedules based on actual equipment health

Reduced downtime and repair costs

Improved equipment performance and reliability

Extended bearing and machine life

🔬 Our Predictive Maintenance Approach

Data Collection: High-accuracy vibration and ultrasonic measurements.

Condition Assessment: FFT spectrum and envelope analysis to detect bearing faults.

Root Cause Diagnosis: Identify source of failure—mechanical, lubrication, or installation-related.

Action Plan: Provide maintenance recommendations and corrective actions.

Periodic Monitoring: Trend analysis to track bearing health over time.

🌟 Why Choose Mech Tech Global

✅ Certified vibration and reliability engineers

✅ Use of advanced analyzers (9080, 107VF, Fluke, etc.)

✅ Comprehensive predictive maintenance solutions

✅ Quick turnaround with detailed diagnostic reports

✅ Trusted by top industrial clients across India

🧾 Industries We Serve

Power Generation & Utilities

Cement, Steel & Mining

Petrochemical & Refinery

Automotive & Process Plants

Paper, Textile & Food Industries

📞 Contact Us

For bearing condition analysis and predictive maintenance services, connect with Mech Tech Global today:

🔍 SEO Keywords for Google Optimization

Bearing condition monitoring services India

Predictive maintenance for rotating machinery

Bearing vibration analysis

Early bearing fault detection

Machinery health monitoring

Condition-based maintenance solutions

Bearing diagnostics and predictive analytics

Industrial maintenance service Delhi NCR

| Type | Balancing Service |

| Service Mode | Offline |

| Payment Mode | Online & offline |

| Usage | Fans, Motors, Blowers, Pumps |

| Balancing Types | Dual Plane |

| Balancing Capabilities | Industrial Fans, Blowers, Electric Motors Etc |

| Balancing Process | Vibration Measurement, Balancing Plane Determination |

Balancing services (single & dual plane) for fans, motors, blowers, and pumps

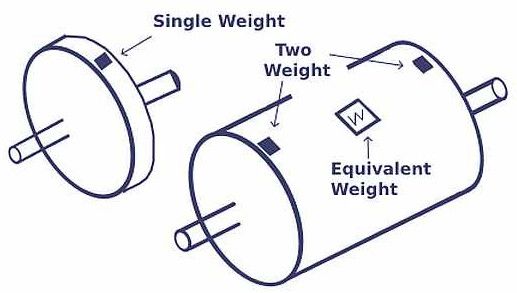

Dynamic Balancing Services (Single & Dual Plane) for Fans, Motors, Blowers, and Pumps

At Mech Tech Global, we specialize in precision dynamic balancing services for rotating machinery to reduce vibration, extend equipment life, and improve operational efficiency. Our expert team performs single and dual-plane balancing both on-site and in our service facility, using advanced balancing analyzers and certified procedures.

⚙️ Our Balancing Capabilities

We provide professional balancing for:

Industrial Fans and Blowers

Electric Motors and Pump Rotors

Couplings, Impellers, and Pulleys

Turbine Rotors and Shafts

Whether you require field balancing at your site or shop balancing, our engineers ensure your machinery operates within acceptable ISO vibration limits.

📈 Benefits of Our Balancing Services

Elimination of excessive vibration and noise

Reduction in bearing and coupling failures

Extended equipment life and reliability

Enhanced production efficiency

Lower maintenance and energy costs

🔧 Balancing Process

Initial Vibration Measurement – Assess unbalance levels using portable vibration analyzers.

Balancing Plane Determination – Identify single or dual-plane correction needs.

Correction Weight Application – Add or remove precise counterweights.

Verification Run – Confirm reduced vibration levels and ensure balance accuracy.

Final Report – Provide a detailed balancing report with before-and-after data.

🌟 Why Choose Mech Tech Global

✅ Experienced vibration and balancing engineers

✅ State-of-the-art balancing instruments and analyzers

✅ On-site service capability for all rotating equipment

✅ Fast turnaround and reliable reporting

✅ Compliance with ISO 1940/1 and industrial standards

🧾 Industries We Serve

Power Generation & Utilities

Steel, Cement, and Paper Industries

Petrochemical and Manufacturing Plants

HVAC and Building Maintenance

Automotive and Process Industries

📞 Contact Us

For expert dynamic balancing services in India, contact Mech Tech Global today:

🔍 SEO Keywords for Google Optimization

Dynamic balancing services India

On-site fan and motor balancing

Dual-plane balancing service Delhi NCR

Industrial blower balancing

Rotor and pump balancing

Condition monitoring and balancing services

Field balancing experts in India

| Type | On Site Fan Motor Balancing Service |

| Equipment Serviced | Fans, Motors |

| Service Mode | Offline |

| Benefits | Extended Life, Enhanced Efficiency |

| Payment Mode | Online & Offline |

| Service Provider | Mech Tech Global |

| Service Location | On Site |

| Duration | 2 To 3 Days |

Balancing services (single & dual plane) for fans, motors, blowers, and pumps

Dynamic Balancing Services (Single & Dual Plane) for Fans, Motors, Blowers, and Pumps

At Mech Tech Global, we specialize in precision dynamic balancing services for rotating machinery to reduce vibration, extend equipment life, and improve operational efficiency. Our expert team performs single and dual-plane balancing both on-site and in our service facility, using advanced balancing analyzers and certified procedures.

⚙️ Our Balancing Capabilities

We provide professional balancing for:

Industrial Fans and Blowers

Electric Motors and Pump Rotors

Couplings, Impellers, and Pulleys

Turbine Rotors and Shafts

Whether you require field balancing at your site or shop balancing, our engineers ensure your machinery operates within acceptable ISO vibration limits.

📈 Benefits of Our Balancing Services

Elimination of excessive vibration and noise

Reduction in bearing and coupling failures

Extended equipment life and reliability

Enhanced production efficiency

Lower maintenance and energy costs

🔧 Balancing Process

Initial Vibration Measurement – Assess unbalance levels using portable vibration analyzers.

Balancing Plane Determination – Identify single or dual-plane correction needs.

Correction Weight Application – Add or remove precise counterweights.

Verification Run – Confirm reduced vibration levels and ensure balance accuracy.

Final Report – Provide a detailed balancing report with before-and-after data.

🌟 Why Choose Mech Tech Global

✅ Experienced vibration and balancing engineers

✅ State-of-the-art balancing instruments and analyzers

✅ On-site service capability for all rotating equipment

✅ Fast turnaround and reliable reporting

✅ Compliance with ISO 1940/1 and industrial standards

🧾 Industries We Serve

Power Generation & Utilities

Steel, Cement, and Paper Industries

Petrochemical and Manufacturing Plants

HVAC and Building Maintenance

Automotive and Process Industries

📞 Contact Us

For expert dynamic balancing services in India, contact Mech Tech Global today:

🔍 SEO Keywords for Google Optimization

Dynamic balancing services India

On-site fan and motor balancing

Dual-plane balancing service Delhi NCR

Industrial blower balancing

Rotor and pump balancing

Condition monitoring and balancing services

Field balancing experts in India

| Type | Vibration Analysis Service |

| Expertise | Real-time Vibration Analysis, Balancing, And Troubleshooting |

| Approach | Data Collection, Fault Diagnosis |

| Tools | Latest Portable Vibration Analyzers (9080, 107VF, Etc.) |

| Response Time | Quick On-site Response And Detailed Reporting |

Condition Monitoring Services

On-site vibration analysis and diagnostics for rotating machinery

On-site Vibration Analysis and Diagnostics for Rotating Machinery

At Mech Tech Global, we provide comprehensive on-site vibration analysis and diagnostic services to help industries maintain peak equipment performance and minimize unplanned downtime. Our team of certified vibration experts utilizes advanced vibration analyzers and condition monitoring tools to detect faults early and ensure the reliable operation of rotating machinery.

⚙️ Our Expertise

We offer real-time vibration analysis, balancing, and troubleshooting services for all types of rotating and reciprocating equipment, including:

Pumps, Motors, Fans, and Blowers

Compressors and Turbines

Gearboxes and Couplings

Generators and Conveyors

Our diagnostics help in identifying issues such as:

Unbalance

Misalignment

Bearing Defects

Looseness

Resonance

Gear and Shaft Faults

📊 Our Approach

Data Collection – On-site measurement using high-precision vibration analyzers and sensors.

Fault Diagnosis – Detailed analysis using FFT spectrum, time waveform, and phase data.

Root Cause Identification – Accurate detection of mechanical and structural issues.

Corrective Recommendations – Actionable solutions to improve machine reliability.

Report & Consultation – Comprehensive diagnostic reports with trend data and expert advice.

🌟 Why Choose Mech Tech Global

✅ Certified condition monitoring professionals

✅ Use of latest portable vibration analyzers (9080, 107VF, etc.)

✅ Quick on-site response and detailed reporting

✅ Support for predictive maintenance programs (PdM)

✅ Customized solutions for industrial and OEM clients

🧩 Industries We Serve

Power Generation

Cement & Steel

Petrochemical & Refinery

Manufacturing & Automotive

Water & Wastewater Treatment

Paper & Textile Industries

🧾 Deliverables

Vibration severity charts and trend analysis

Fault frequency identification

RMS, FFT, and time-domain plots

Expert recommendations for corrective maintenance

📞 Contact Us

For on-site vibration analysis and diagnostic services, contact our condition monitoring specialists today:

Mech Tech Global

📧 Email: mechtechglobal18@

📞 Mobile / WhatsApp: +91 97110 75595

🌐 Web: Address: X/1070, Street No.3, New Chand Mohalla, Gandhi Nagar, Delhi – 110031, India

🔍 SEO Keywords for Google Optimization

On-site vibration analysis service India

Rotating machinery diagnostics

Vibration testing and condition monitoring

Predictive maintenance vibration analysis

Machinery vibration troubleshooting

Industrial vibration monitoring services

Vibration analyzer service Delhi NCR

Condition monitoring company India

| Type | Diagnostics Service |

| Usage | Rotating Machinery Condition Monitoring |

| Expertise | Real-time Analysis |

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Duration | 3 To 4 Days |

| ResponseTime | Quick On-site Response And Detailed Reporting |

Condition Monitoring Services

On-site vibration analysis and diagnostics for rotating machinery

On-site Vibration Analysis and Diagnostics for Rotating Machinery

At Mech Tech Global, we provide comprehensive on-site vibration analysis and diagnostic services to help industries maintain peak equipment performance and minimize unplanned downtime. Our team of certified vibration experts utilizes advanced vibration analyzers and condition monitoring tools to detect faults early and ensure the reliable operation of rotating machinery.

⚙️ Our Expertise

We offer real-time vibration analysis, balancing, and troubleshooting services for all types of rotating and reciprocating equipment, including:

Pumps, Motors, Fans, and Blowers

Compressors and Turbines

Gearboxes and Couplings

Generators and Conveyors

Our diagnostics help in identifying issues such as:

Unbalance

Misalignment

Bearing Defects

Looseness

Resonance

Gear and Shaft Faults

📊 Our Approach

Data Collection – On-site measurement using high-precision vibration analyzers and sensors.

Fault Diagnosis – Detailed analysis using FFT spectrum, time waveform, and phase data.

Root Cause Identification – Accurate detection of mechanical and structural issues.

Corrective Recommendations – Actionable solutions to improve machine reliability.

Report & Consultation – Comprehensive diagnostic reports with trend data and expert advice.

🌟 Why Choose Mech Tech Global

✅ Certified condition monitoring professionals

✅ Use of latest portable vibration analyzers (9080, 107VF, etc.)

✅ Quick on-site response and detailed reporting

✅ Support for predictive maintenance programs (PdM)

✅ Customized solutions for industrial and OEM clients

🧩 Industries We Serve

Power Generation

Cement & Steel

Petrochemical & Refinery

Manufacturing & Automotive

Water & Wastewater Treatment

Paper & Textile Industries

🧾 Deliverables

Vibration severity charts and trend analysis

Fault frequency identification

RMS, FFT, and time-domain plots

Expert recommendations for corrective maintenance

📞 Contact Us

For on-site vibration analysis and diagnostic services, contact our condition monitoring specialists today:

Mech Tech Global

📧 Email: mechtechglobal18@

📞 Mobile / WhatsApp: +91 97110 75595

🌐 Web: Address: X/1070, Street No.3, New Chand Mohalla, Gandhi Nagar, Delhi – 110031, India

🔍 SEO Keywords for Google Optimization

On-site vibration analysis service India

Rotating machinery diagnostics

Vibration testing and condition monitoring

Predictive maintenance vibration analysis

Machinery vibration troubleshooting

Industrial vibration monitoring services

Vibration analyzer service Delhi NCR

Condition monitoring company India

| Type | Balancing Service |

| Equipment Serviced | Roto, Pumps |

| Service Mode | Offline |

| Benefits | Enhanced Efficiency |

| Payment Mode | Online & Offline |

| Duration | 2 To 3 Days |

| Service Location | On-site And Service Facility |

| Certification | Compliance With ISO 1940/1 And Industrial Standards |

Balancing services (single & dual plane) for fans, motors, blowers, and pumps

Dynamic Balancing Services (Single & Dual Plane) for Fans, Motors, Blowers, and Pumps

At Mech Tech Global, we specialize in precision dynamic balancing services for rotating machinery to reduce vibration, extend equipment life, and improve operational efficiency. Our expert team performs single and dual-plane balancing both on-site and in our service facility, using advanced balancing analyzers and certified procedures.

⚙️ Our Balancing Capabilities

We provide professional balancing for:

Industrial Fans and Blowers

Electric Motors and Pump Rotors

Couplings, Impellers, and Pulleys

Turbine Rotors and Shafts

Whether you require field balancing at your site or shop balancing, our engineers ensure your machinery operates within acceptable ISO vibration limits.

📈 Benefits of Our Balancing Services

Elimination of excessive vibration and noise

Reduction in bearing and coupling failures

Extended equipment life and reliability

Enhanced production efficiency

Lower maintenance and energy costs

🔧 Balancing Process

Initial Vibration Measurement – Assess unbalance levels using portable vibration analyzers.

Balancing Plane Determination – Identify single or dual-plane correction needs.

Correction Weight Application – Add or remove precise counterweights.

Verification Run – Confirm reduced vibration levels and ensure balance accuracy.

Final Report – Provide a detailed balancing report with before-and-after data.

🌟 Why Choose Mech Tech Global

✅ Experienced vibration and balancing engineers

✅ State-of-the-art balancing instruments and analyzers

✅ On-site service capability for all rotating equipment

✅ Fast turnaround and reliable reporting

✅ Compliance with ISO 1940/1 and industrial standards

🧾 Industries We Serve

Power Generation & Utilities

Steel, Cement, and Paper Industries

Petrochemical and Manufacturing Plants

HVAC and Building Maintenance

Automotive and Process Industries

📞 Contact Us

For expert dynamic balancing services in India, contact Mech Tech Global today:

🔍 SEO Keywords for Google Optimization

Dynamic balancing services India

On-site fan and motor balancing

Dual-plane balancing service Delhi NCR

Industrial blower balancing

Rotor and pump balancing

Condition monitoring and balancing services

Field balancing experts in India