mechtechglobal18@gmail.com - GST NO. : 07AWSPR4832K1ZS

- Send Email

| Business Type | Exporter, Supplier, Trader |

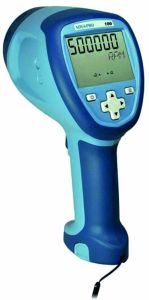

| Technical Data Sheet – LD 500 / LD 510 Ultrasonic Leak Detector | |

| Power Source | Battery, 9V Battery |

| Application | Detecting Air And Gas Leaks |

| Click to view more | |

Product Details

Items Included:

LD 500 Leak Detector with UltraCam, Transport Case, Sound-proof Headset, Focus Tube with Focus Tip, AC Adapter Plug, Spiral Connection Cable (2 m extended), Holster with Shoulder Strap

LD500 Ultrasonic Leak Detector by Mech Tech Global: Identify compressed air, gas, steam and vacuum leaks with precision. Calculate leak rate, cost impact and improve energy efficiency.

Product OverviewThe LD500 Ultrasonic Leak Detector is a high-performance instrument designed for accurately locating leaks in compressed air, gas and vacuum systems. It features integrated photographic documentation, real-time leak-rate calculation (l/min) and cost-estimation capabilities. Maintenance teams can quickly identify, record and quantify leak losses, enabling effective energy-saving and maintenance planning. Its long battery life and auto-level sensitivity control make it ideal for industrial maintenance and audit operations.

Key Features & Benefits-

Leak-rate and cost calculation displayed directly on the device screen

-

Integrated camera for documenting leak locations and conditions for reporting

-

Auto-level sensitivity adjustment to eliminate background noise

-

LED display and touchscreen interface for easy operation

-

Long battery life (~9 hours continuous use)

-

Multiple accessories including tubular probe, gooseneck and parabolic mirror for hard-to-reach locations

-

Data export and reporting capability for audit documentation

-

Supports ISO 50001 energy-management reporting

Perfect for:

-

Compressed air lines, pneumatic systems, fittings and regulators

-

Steam system leaks and non-flammable gas pipelines

-

Vacuum systems and robotic automation equipment

-

Automotive and tyre service facilities

-

HVAC, refrigeration & energy audit applications

-

Preventive and predictive maintenance programs

Mech Tech Global specializes in industrial diagnostic and condition monitoring instruments. By choosing the LD500 Ultrasonic Leak Detector from us, customers benefit from:

-

Expert technical consultation and product selection guidance

-

Local service, calibration and maintenance support across India

-

Product training for maintenance and reliability teams

-

Strong after-sales support and availability of accessories & spare parts

-

Ability to integrate leak audits into plant energy-saving programs

-

Power on the detector and allow auto-sensitivity adjustment

-

Use the appropriate attachment (parabola, tubular probe, gooseneck) to scan suspected leak zones

-

View leak value (l/min) and cost estimation directly on the screen

-

Capture photo of leak area for record & reporting

-

Download stored data and generate a maintenance or audit report

-

Prioritise repairs based on leak-cost severity

-

Detection frequency: approx. 40 kHz ultrasonic range

-

Leakage measurement: l/min with annual cost estimation

-

Display: 3.5” touchscreen with LED visualization

-

Battery: Rechargeable Li-ion (up to 9 hours continuous)

-

Data storage: Exportable via USB / SD

-

Included accessories: Parabolic mirror, acoustic trumpet, gooseneck probe, earbuds, carrying case

Leaks in compressed air and gas networks commonly waste 10–30% of system energy. The LD500 enables:

-

Immediate leak identification & repair prioritization

-

Significant reduction in power consumption and compressor load

-

Increased system reliability and safety

-

Documented ROI through cost-based reporting.

Technical Data Sheet – LD 500 / LD 510 Ultrasonic Leak Detector